Service Hotline

ZhiJian Hardware Products Co., Ltd发布时间:2021-12-24

The production process and technical standards of the metal material dome sheet is made of PET tape paper and 301 stainless steel plate. The PET tape paper is divided into transparent and milky white and high temperature resistance. Divided into single-sided exhaust holes and two-layer exhaust pipe slots, the metal material distributors of the dome 301 are Japan, Toyo, JCM, etc., which can be manufactured according to customer quality requirements: gold-plated dome, gold-plated dome, Electroplated nickel dome and stainless steel plate dome.

1. The use of raw materials.

The use of dome pieces: the common dome pieces are ring, oval, cross, and triangle. Customers can use the dome pieces according to their own product regulations. The most common one on the market is the ring, which has low cost, high service life and good reliability. The material of the dome is divided into stainless steel plate, nickel plating, gold plating, and gold plating, and their resistance is gradually reduced in this order. In other words, electroplated gold has the least resistance. Customers can choose materials according to their requirements. The use of plastic materials: the common plastic materials are fully transparent and milky white.

1. Transparent tape: It is very easy to align when it is attached to the PCB. After attaching it, you can see whether there is any stain or deviation.

2. Milky white rubber material: The milky white raw material mainly has a certain effect of returning light to the functional keys containing lamp holes.

Second, the assembly process and the assembly of the PCB board.

1. Assembly station, the assembly needs to be done after the PCB patch type, and then go to the pot type patch type, because the maximum temperature that PET can pass is 100°, and the limit temperature is 120°.

2. Before assembly, it is necessary to clean up the surface of the PCB (it is recommended to use it to scrub with water, also known as: Tianna water).

3. The actual operating staff must wear gloves when tearing off the pot patch, and must maintain the cleanup of the natural environment.

4. It is suggested to rely on simple fixtures to close together, to ensure that the dome patch type does not go around, and at the same time, it can also improve productivity.

3. PCB package solder layer design scheme.

1. The diameter of the welding layer is proposed to be 0.5mm larger than the diameter of the dome. For example: a dome sheet with a diameter of 4mm is matched with a welding layer with a diameter of 4.5mm, and a dome sheet with a diameter of 5mm is matched with a welding layer with a diameter of 5.5mm.

2. It is suggested that the inner diameter of the welding layer should be guaranteed to be 2-2.5mm, the total width of the insulating layer in the middle should be 1.0mm, and the total diameter of the area should be 2.5-3.5mm. Taking the dome sheet with a diameter of 5mm as an example, the insulating layer area is 3.5mm,

3. It is suggested to use gold electroplating to solve the problem of touching the area, because electroplating will improve the conductivity between the pot and the pcb circuit board. At the same time, the thickness of the electroplating gold should be sufficient, otherwise the coating will fall off and cause The on-off is not good, it can actually be mastered with the PCB manufacturer.

Advantage

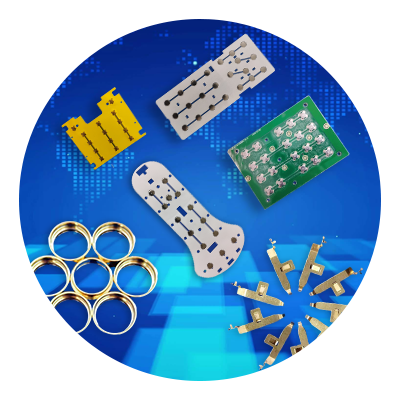

The company has created a group of high-quality staff, and is a medical accessories service provider integrating design, research and development, production, sales and service. Main products: dome pieces, metal shrapnel, precision hardware, etc.

On the basis of a win-win situation, we provide the most competitive price of pot pieces, implement ordering, supply, and after-sales services, and fully and quickly meet customer requirements for special models and large-scale needs.

Zhijian Hardware is located in Dongguan City, the center of the Pearl River Delta, The transportation hub area is developed and the delivery is convenient and fast.

Passed IS09000:2015 quality management certification, ERP management system, project management and many other qualification certifications, from customer service, internal control, standardized system guidance and daily review and improvement.

One-stop dome manufacturer, complete dome supply chain: chemical gold plating factory, SMT patch factory, mold, provide technical support within 24 hours, help customers design and select models, and solve the difficult problem of customer selection.